February 18, 2026 - 6 minutes read

How Advanced Software Improves Visibility and Modern Supply Chain Management

Supply chains are under more pressure than ever, yet many organizations are still running operations on outdated technology that can’t keep up. Rising customer expectations, global volatility, and near-immediate fulfillment demands have simply outgrown many legacy systems. Visibility is essential for managing this new level of complexity, but without the right infrastructure in place, most companies are still stuck reacting to problems after they occur.

Modern supply chain software helps connect siloed systems, automate the flow of information, and support real-time decisions across global operations. Yet the process isn’t easy or always successful. In fact, according to Forbes, 70–80% of digital transformation programs fail to meet their intended objectives.

This blog explores how emerging supply chain management software can help organizations avoid those pitfalls. We’ll cover what’s driving the shift, which technologies matter most, and how comprehensive visibility platforms support scalable, long-term transformation.

Understanding Modern Supply Chain Management

Supply chain management has always been about coordinating the movement of goods, information, and capital. But today’s supply chains look nothing like they did even a decade ago. Globalization, e-commerce, and real-time fulfillment have pushed supply chain operations beyond the traditional factory-to-warehouse-to-retail model.

Modern supply chain management (SCM) reflects this shift. It’s a technology-driven discipline that connects partners, platforms, and processes through centralized systems and intelligent automation. Unlike traditional SCM, which focused largely on cost control and internal efficiency, modern SCM prioritizes agility, resilience, and end-to-end collaboration. It relies on integrated software to manage:

- Material flows: The movement of goods across increasingly complex, multi-tiered networks.

- Information flows: The real-time data that powers forecasting, tracking, and exception management.

- Financial flows: The billing, invoicing, and payment cycles that impact cash flow and partner performance.

Today, software solutions are at the core of strategic supply chain management — not just supporting operations, but helping to shape them.

Get deeper insights into supply chain management strategy and future of logistics in our related analysis.

How Modernizing Supply Chain Software Enhances Visibility

Visibility depends on more than just access to tracking data — it requires connected systems, clean data, and real-time context across every stage of the order-to-invoice lifecycle. That’s why software modernization plays such a critical role. By eliminating the silos and inconsistencies that legacy systems create, advanced software solutions enable a more accurate and actionable view of supply chain performance.

Key elements include:

- Systems integration: Connecting ERP, TMS, WMS, and third-party platforms into a single operational view, regardless of vendor or format.

- Cloud-based infrastructure: Supporting real-time analytics, faster data processing, and flexible access across global operations.

- Data standardization: Aligning disparate formats into a unified framework for reporting, decision-making, and automation.

When systems work together and data flows freely, organizations gain the visibility needed to move from reactive firefighting to proactive, insight-driven execution.

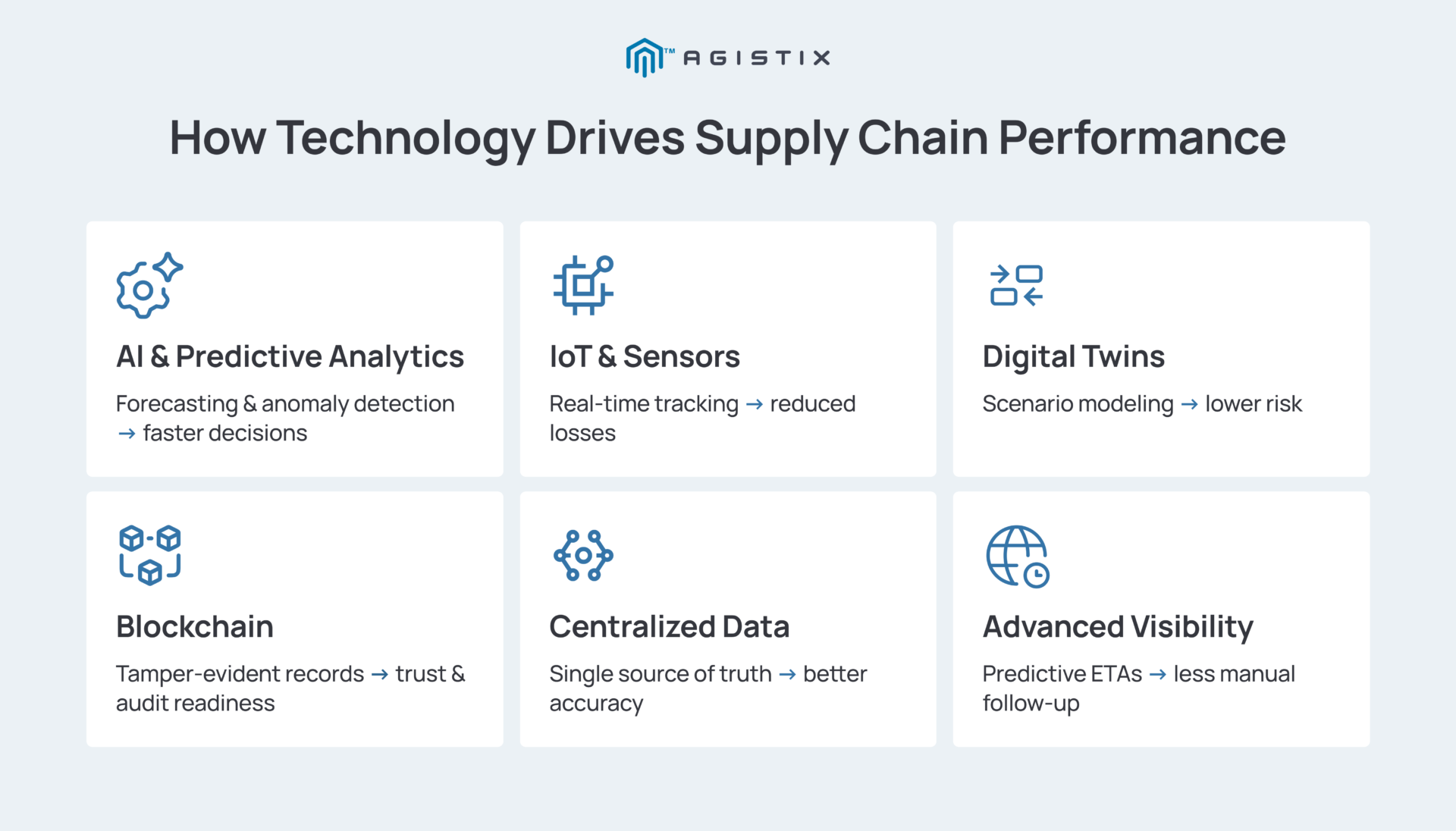

The Technology Innovations Driving Digital Transformation in Logistics and Supply Chain

Supply chain management today is defined by its technology stack. As operations become more complex, businesses are turning to custom-built tools that deliver clarity, speed, and strategic insight. These innovations are reshaping how organizations manage risk, track performance, and make decisions across global networks.

Artificial Intelligence and Predictive Analytics

AI enables supply chains to move faster by anticipating what’s coming next. From demand forecasting to anomaly detection and exception resolution, utilizing AI in supply chain visibility helps teams make decisions before problems escalate. These systems can process millions of data points at once — far beyond human capability — enabling smarter, real-time responses.

IoT and Sensor-Driven Visibility

Connected devices offer granular insight into shipment status and condition. IoT sensors track temperature, humidity, shock, dwell time, and location instantaneously, providing context beyond traditional scan events. This level of visibility is essential for high-value, time-sensitive, or regulated goods and supports faster resolution when shipments fall outside of expected thresholds.

Digital Twins for Scenario Planning and Risk Insight

Digital twins are virtual replicas of a supply chain’s physical and operational network. By modeling different scenarios, companies can test responses, evaluate outcomes, and build contingency plans before disruptions occur. The result is a better-informed strategy and reduced exposure to risk.

Blockchain for Trust and Accountability

While not the newest tool, blockchain remains relevant in high-compliance environments. It provides a secure, tamper-evident record of every transaction or movement within a supply chain. This traceability improves accountability across partners, reduces fraud, and strengthens audit readiness — especially in regulated industries like pharmaceuticals and aerospace.

Centralized Data Management Platforms

Data fragmentation continues to be one of the biggest barriers to visibility. Centralized platforms bring together information from multiple systems, normalize it, and create a single source of truth. This enables more accurate analysis, reliable reporting, and reduced noise that often clouds decision-making.

Advanced Visibility Capabilities

The most valuable visibility tools go far beyond track-and-trace. Milestone correlation, predictive ETAs, exception-based alerts, and multimodal shipment views give teams full lifecycle insight — from PO to final delivery. These features reduce manual follow-ups and create the operational clarity that most legacy systems lack.

How Visibility Platforms Enable Supply Chain Modernization

Visibility platforms serve as the connective layer across complex supply chain systems. They unify data from disparate sources — ERPs, TMS, WMS, carrier portals, and more — into a single, trusted source of truth. This allows teams to see what’s happening, where, and why, without switching between systems or relying on manual updates and spreadsheets.

When applied at scale, this level of visibility improves service performance, strengthens cost control, and supports better working capital management. Organizations resolve exceptions faster, reduce avoidable accessorial costs, and spend less time on manual freight audit and invoice reconciliation — all while maintaining tighter control over logistics spend and tariff-related cost pressures.

With real-time access to shipment, order, and invoice data, visibility platforms help organizations:

- Correlate milestones across modes, systems, and partners to maintain continuity and accountability

- Accelerate decisions with timely, contextual insight

- Improve collaboration across internal teams, suppliers, and logistics providers

- Identify risks early and manage exceptions before they impact performance

- Monitor contract compliance and surface unexpected surcharges or accessorials before they show up on final invoices — particularly important given the material impact detention and demurrage charges can have when visibility is limited

By centralizing insight and surfacing issues in real time, visibility platforms give organizations the control and transparency needed to support modern supply chain management, without replacing systems or existing processes.

Accelerating Modern Supply Chain Management with Agistix

Modern supply chain management depends on more than visibility alone — it requires the ability to integrate systems, act on real-time data, and collaborate across a global network. Agistix is a digital logistics platform designed to help leading enterprises modernize without disrupting what already works.

By centralizing shipment, order, and invoice data across systems and partners, Agistix supports connected infrastructure, unified data management, and full lifecycle visibility. It also extends beyond insight into action, helping teams manage exceptions, monitor performance, and align with suppliers and carriers in real time — all essential components of a scalable, modern supply chain.

Frequently Asked Questions

- Real-time shipment, order, and invoice visibility

- Milestone correlation across modes, systems, and partners

- Exception-based alerts with context for resolution

- Accurate ETAs and performance analytics

- Integration with ERPs, TMSs, WMSs, and carrier portals

- Support for supplier and 3PL collaboration * Automated audit of contract rates and invoice validation

- Centralized data standardization and reporting

- Scalable architecture that doesn’t require process change

The right platform will give companies the insight they need and the tools to act on it.