December 14, 2025 - 11 minutes read

What Is Supply Chain Management and Why It Matter?

What is Supply Chain Management? Strategy, Technology, and the Future of Logistics

The modern supply chain is a powerful engine – and a substantial risk point – in the global economy. For modern enterprises, supply chain management (SCM) has moved beyond basic execution and is a foundation for market advantage and resilience. No longer seen as a mere cost center, the supply chain is a critical lever for growth; yet success hinges on a company’s ability to manage volatility and ensure real-time, accurate data across all stakeholders.

This article explores why strategic supply chain management matters for business continuity and how technology, visibility, and intelligent planning will drive the next generation of efficient, profitable, end-to-end operations.

What is Supply Chain Management (SCM)?

SCM is the comprehensive planning and execution of all activities involved in sourcing, procurement, production, and logistics. Above all, it is the strategic coordination and collaboration with various partners, including suppliers, 3PLs, and customers, to integrate supply and demand management both within and across companies.

While often confused with logistics, supply chain operations are far broader. They encompass the integrated management of three critical flows across the value chain:

- Material Flow: The physical movement of raw materials, work-in-progress, and finished goods from the supplier network to production centers and the end consumer.

- Information Flow: The real-time, bi-directional exchange of data – from demand forecasts and sales orders to shipment tracking and inventory levels – that synchronizes the supply chain network.

- Financial Flow: The management of payments, invoices, credit terms, and consignment arrangements that ensures the financial health of an organization.

The Evolution of Supply Chain Management

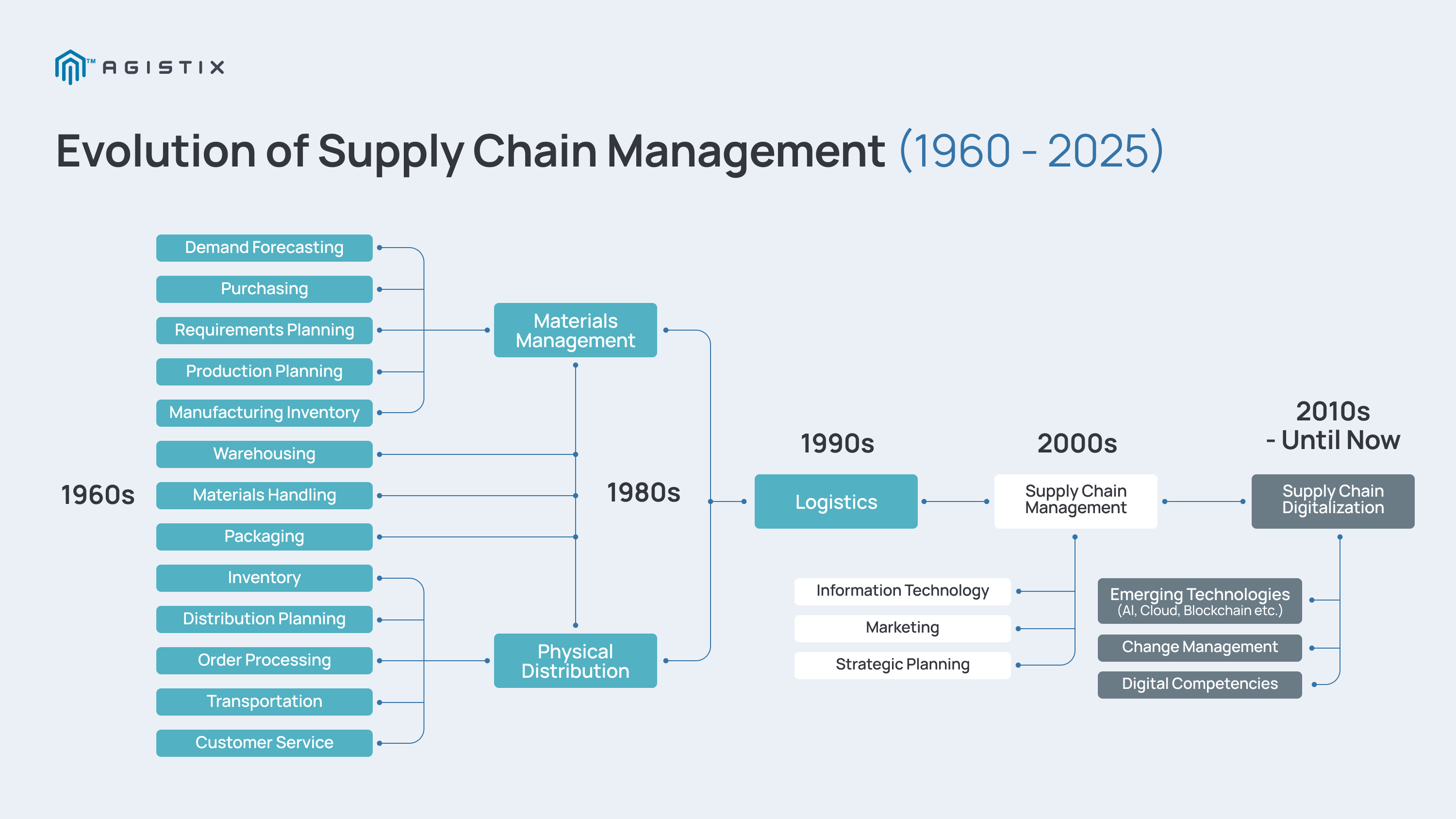

The roots of SCM go back to the early 20th century with the refinement of assembly lines, but the concept emerged as a distinct strategic discipline in the 1980s. Initially, the focus was primarily internal: improving manufacturing efficiency, optimizing inventory levels, and tightly managing costs within a company’s four walls. As global trade accelerated, SCM evolved to incorporate international logistics and supplier management, connecting domestic processes to vast, complex networks spanning continents.

The massive growth of e-commerce accelerated the transition from traditional retail-centric models to complex direct-to-consumer operations. This shift altered SCM dynamics, requiring more flexible supply chains capable of handling smaller, more frequent deliveries globally. Today, the continuous need for end-to-end transparency and responsiveness, driven by advancements in data technology, defines modern SCM as a discipline focused on strategic risk mitigation.

How SCM Supports Business Continuity and Customer Satisfaction

SCM is an essential mechanism for maintaining operational stability and securing brand loyalty amid market volatility.

- Proactive Risk Mitigation: A robust SCM plan, paired with advanced logistics visibility software, enables companies to anticipate and respond to various risks, such as material shortages, geopolitical events, and freight delays. This ability to quickly launch contingency plans ensures business continuity in the face of inevitable disruption, protecting revenue and market access.

- Customer Experience: Customer expectations demand flawless execution. Effective supply chain logistics ensures the right product is delivered to the right place at the right time, minimizing costly service failures. A disciplined SCM approach to execution and on-time performance builds trust and strengthens consumer sentiment toward the brand.

Why Supply Chain Management Matters

In addition to mitigating immediate risk and improving customer experience, SCM directly impacts a company’s financial performance, competitive positioning, and long-term viability. It transforms the end-to-end network into a source of disciplined, profitable growth.

- Operational Efficiency: Comprehensive SCM should aim to maximize resource utilization and speed, ensuring capital assets and logistics networks operate at peak performance. It should also streamline workflows to reduce redundancy and automate manual tasks where possible, setting a benchmark for enterprise-wide excellence.

- Cost Control and Capital Optimization: SCM maximizes capital efficiency and improves cash flow by balancing inventory levels, strategically optimizing supplier payment terms, and consolidating high-volume freight. This directly enhances an organization’s financial health and profitability.

- Adaptability and Resilience: The shift from solely focusing on efficiency to prioritizing resilience is now an executive imperative – Gartner reports that 70% of CEOs consider supply chain resilience a top business priority. Strategic SCM builds this adaptability through network diversification and advanced scenario planning, allowing the business to recover quickly from disruption and volatility.

- Sustainability and ESG Compliance: By integrating sustainability metrics into core processes, SCM enables the measurement and reduction of a company’s largest carbon footprint source (Scope 3 emissions), which is essential for regulatory compliance and attracting capital investment.

Key Components of Supply Chain Management

To achieve end-to-end control and drive strategic value, supply chain management relies on integrating five core functional areas. The success of the network depends on accurate, real-time data flowing between them.

- Procurement and Supplier Management: Sourcing raw materials and services, managing contractual relationships, and continuously evaluating supplier performance and risk exposure across the network.

- Production and Inventory Control: Coordinates manufacturing activities and schedules to ensure optimal material flow. It focuses on maintaining the right balance of finished goods and raw materials to meet demand without excessive carrying costs.

- Logistics and Distribution: The execution engine responsible for the physical movement and storage of goods. Activities include transportation planning, warehousing, route optimization, and last-mile delivery.

- Demand Forecasting and Analytics: Using historical data, market trends, and advanced models to predict future customer demand to align supply capabilities. It also helps to manage costs against tariffs or other unexpected fluctuations to maintain business continuity.

- Reverse Logistics and Sustainability Initiatives: Addressing the post-consumer phase, managing product returns, recycling, and disposal. It also encompasses implementing sustainability metrics and practices (e.g., carbon tracking) across the entire value chain.

Common Challenges in Supply Chain Management

Despite the importance of logistics operations and supply chain management, organizations frequently encounter obstacles that limit efficiency and compromise resilience. These challenges must be addressed with a clear strategy to unlock sustained performance.

- Fragmented Systems and Data Silos: Most global supply chains operate across numerous disconnected legacy systems, leading to incompatible data formats that prevent real-time visibility needed for intelligent decision-making.

- Lack of Visibility Across Global Suppliers: Limited insight into the activities of N-tier suppliers and third-party logistics providers (3PLs) creates blind spots, hindering a company’s ability to proactively manage risk or resolve shipment exceptions.

- Rising Transportation Costs and Sustainability Pressures: High fuel costs, labor shortages, and freight tariffs constantly squeeze margins, while shippers must balance cost-reduction goals with growing regulatory demands for greener transportation methods.

- Talent and Digital Skill Shortages: The rapid shift to digital supply network platforms has created a significant gap, leaving many companies struggling to find talent capable of managing advanced analytics, AI tools, and complex data environments.

How Technology Is Transforming SCM

The technology stack now drives the most significant competitive distinction in modern supply chains. Facing chronic volatility, leading organizations are leveraging advanced digital tools and robust supply chain management software to shift from reactive management to proactive, predictive operations. These are the critical technologies reshaping the industry:

- Agentic AI for Autonomous Task Execution: Advanced AI models are moving beyond simple data processing to execute complex, multi-step tasks, such as autonomously rerouting freight or reordering materials, to handle exceptions with minimal human intervention.

- Decision Intelligence Platforms: These platforms integrate and analyze massive data sets from across the network, providing executives with actionable, contextual insights instead of raw data. Deloitte highlights that digital supply networks can improve decision-making speed by up to 25%.

- Autonomous Data Capture: Technology that automatically extracts, validates, and normalizes critical data, including supplier information, shipment milestones, and customs documents, reduces manual effort and ensures the entire network operates from a single source of truth.

- Digital Twins for Scenario Modeling: Virtual, dynamic representations of the physical supply chain allow managers to run sophisticated “what-if” scenarios, stress-testing the network against potential disruptions to optimize contingency plans.

- Automation and Workflow Orchestration: The automation of repetitive, rules-based tasks removes friction and accelerates execution. McKinsey notes that SCM automation can reduce operational costs by 30–40%.

- Control Tower–Style Visibility Hubs: These centralized platforms consolidate real-time data from all modes, regions, and partners into a single view. They provide the necessary end-to-end transparency needed for swift exception management and coordinated global execution.

Trends in End-to-End Supply Chain Management for 2026

The convergence of technological advancement and market volatility is forcing SCM leaders to redefine their operating models. For 2026 and beyond, the focus shifts to end-to-end integration, predictive capabilities, and building structurally resilient networks.

Predictive Operations

The next evolution of the supply chain involves shifting the network from reactive event management to proactive forecasting. Leveraging AI and machine learning across massive datasets enables teams to predict outcomes with higher accuracy, enabling intervention before disruptions impact downstream productivity.

Resilient Supply Chain Design

Resilience is a fundamental competitive advantage that must be engineered into the operational blueprint. This requires strategically diversifying the supplier and carrier base, investing in flexible, modular facilities, and continuously stress-testing the supply chain through digital modeling to maintain continuity and protect long-term market access.

End-to-End Integrated Planning

To eliminate costly operational and financial misalignment, leading enterprises are breaking down traditional planning silos between procurement, sales, logistics, and finance. Integrated planning uses a single data model to synchronize processes, ensuring that supply execution, demand forecasting, and financial goals are continuously managed as collaborative functions.

Measuring and Managing ESG Performance

Sustainability is rapidly moving from a marketing initiative to a critical operational requirement driven by regulation and investor pressure. This trend requires SCM to operationalize the tracking and reporting of Scope 3 emissions across the value chain, using granular supply chain data to deliver verifiable ESG metrics and demonstrate compliance.

Platform-Based Stakeholder Collaboration

Holistic SCM is evolving past simple data exchange and toward a shared, platform-based environment. This grants all internal departments and external stakeholders access to the same real-time operational picture. This ensures every relevant party acts on a unified source of truth, accelerating decision-making and improving accountability across the global operation.

Ready to see how leading enterprises are taking control of supply chain management? Schedule a demo of the Agistix platform.

FAQs

1.What is the difference between supply chain management and supply chain logistics?

The distinction is one of scope and strategy. Logistics focuses specifically on the physical movement, storage, and flow of goods (i.e., transportation, warehousing, materials handling). Supply Chain Management (SCM) is a comprehensive, overarching strategy. SCM manages all the internal and external activities across the entire value chain, including sourcing, procurement, production planning, collaboration with suppliers, and logistics. In other words, logistics is just one function within supply chain management.

2.What are the benefits of strategic supply chain management?

Moving beyond simple execution, strategic supply chain management provides a competitive advantage that enhances profitability and builds resilience.

- Optimized Working Capital: Reduces capital tied up in inventory by ensuring materials and finished goods are balanced against demand.

- Superior Risk Mitigation: Provides the visibility and scenario planning tools necessary to manage geopolitical events, supplier failures, and freight disruption proactively.

- Enhanced Customer Experience: Ensures on-time, accurate order fulfillment, minimizing service failures that erode brand trust.

- Compliance and ESG Reporting: Centralizes data needed to rigorously track Scope 3 emissions and meet investor and regulatory demands for sustainability metrics.

- Maximized Operational Efficiency: Streamlines cross-functional workflows, eliminates manual tasks, and accelerates cycle times from order placement to final delivery.

- Strategic Sourcing Power: Centralizes procurement data to enhance negotiation leverage, diversify the supplier base, and reduce acquisition costs for raw materials and services.

3.Why is end-to-end visibility critical for successful supply chain management?

End-to-end visibility transforms a supply chain from a series of disconnected, reactive processes into a unified, proactive system. Visibility provides a real-time view of every order, inventory item, and shipment milestone across all partners and regions.This capability allows teams to anticipate bottlenecks, like port congestion or a carrier delay, and launch immediate contingency plans, cutting transit time variations and improving reliability.

Additionally, visibility should extend to the financial layer. This enables monitoring of contracted rates, unauthorized accessorial fees, and unexpected freight costs, ensuring carriers honor agreements to prevent unnecessary margin erosion.

4.How does supply chain management software improve data accuracy and decision-making?

Supply chain management software solves a fundamental problem of data fragmentation by acting as a single source of truth.

- Centralization and Normalization: The software automatically ingests data from dozens of disparate systems (ERP, WMS, carrier portals) and standardizes it into one format. This eliminates manual data entry errors and ensures consistency across the enterprise.

- Predictive Analytics: The centralized, clean data feeds advanced AI and machine learning models. These models can identify complex, non-obvious patterns, like the impact of weather on demand, far faster than human analysts, enabling precise demand forecasting and scenario modeling for proactive decision-making.

5.What features should I look for in a supply chain management software provider?

When evaluating a supply chain management software provider, focus on core capabilities that deliver actionable control.

- Real-Time Visibility: Should include granular location and status updates for every shipment and order across all modes and carriers.

- System Integration: The platform should easily connect with your existing ERP (like SAP or Oracle), WMS, and financial systems to eliminate data silos and keep internal teams informed.

- Advanced Analytics and Scenario Modeling: Capabilities that move beyond descriptive data to offer predictive forecasting and tools for stress-testing the supply chain against hypothetical disruptions.

- Customizable Functionality: Provides a central dashboard that allows users to set alerts, manage exceptions, and prioritize critical actions in real-time, tailored to specific user roles.

- Supplier Collaboration Tools: Features that facilitate communication and shared data access with external partners to improve accountability and reduce lead times.