January 14, 2026 - 10 minutes read

TMS vs Freight Visibility Platform: What’s the Difference?

Many companies believe they have supply chain visibility, but that doesn’t mean they can actually see what’s happening across their whole network. Too often, what’s called “visibility” stops at basic shipment tracking, leaving financial data, supplier activity, and inbound freight in the dark. To make smarter decisions, businesses need consistent, real-time information across every part of the supply chain. That starts with understanding what supply chain visibility means today, and how to build it the right way.

What is Supply Chain Visibility?

Supply chain visibility (SCV) refers to a company’s ability to access timely, accurate information about goods and data as they move through the supply chain. While it once focused primarily on tracking shipments in transit, the supply chain visibility definition has expanded to include cost data, documentation, service performance, and other operational metrics.

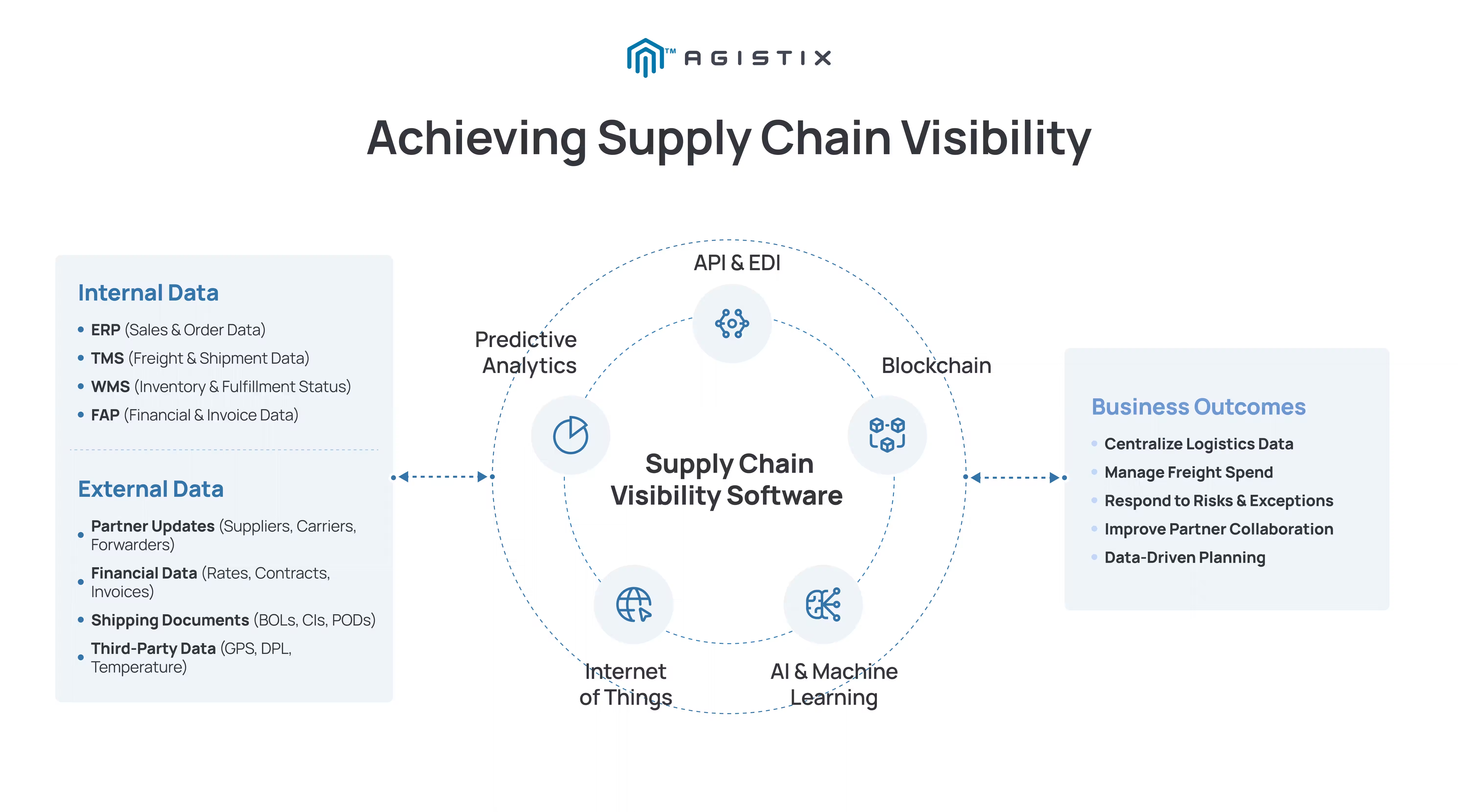

Visibility now spans the entire supply chain, from inbound orders and supplier activity to outbound delivery, partner performance, and financial reconciliation. According to Gartner, 82% of surveyed CEOs plan to increase investments in digital capabilities, specifically those that improve visibility across their supply chain networks. As operations grow more complex, visibility depends on the ability to connect data from multiple internal systems (ERP, WMS, TMS), external partners, and enabling technologies such as IoT, cloud-based platforms, blockchain, and AI to deliver comprehensive insights.

Modern supply chain visibility solutions bring this data together into a single environment. By centralizing information across systems, partners, and shipment types, these platforms enable real-time verification, performance monitoring, and faster, more informed responses. True visibility means seeing everything from the time an order is placed to when an invoice is paid across all modes, geographies, and partners. Without that level of clarity, it’s impossible to plan, collaborate, or respond effectively to disruptions.

Why Does Supply Chain Visibility Matter?

Today’s supply chains rely on real-time information to operate efficiently. When data is delayed, inconsistent, or incomplete, it becomes harder to manage day-to-day operations and plan for what’s ahead. Visibility into supply chain logistics brings structure and clarity to a process that spans systems, partners, and geographies.

Common consequences of poor visibility include:

- Higher freight costs. When teams can’t compare rates or validate invoices, they overpay or miss billing errors entirely.

- Missed service expectations. Late shipments or incomplete deliveries go unnoticed until a customer reports them.

- Slow response to disruptions. By the time teams realize something is wrong, it’s too late to prevent downstream impacts.

- Inefficient workflows. Teams spend hours tracking shipments manually or reconciling mismatched data across systems.

- Poor planning and forecasting. Without reliable data, it’s hard to anticipate delays, manage capacity, or build contingency plans.

While visibility is essential, many businesses struggle to achieve it effectively. That’s because end-to-end supply chain visibility presents challenges that require the right data infrastructure, system integration, and partner alignment. Agistix helps organizations overcome these barriers by connecting order, shipment, and invoice data across systems and partners in a single, unified platform.

Types of Supply Chain Visibility

Visibility applies across different functions within the supply chain. While some types – like shipment tracking – are more familiar, others are equally critical for managing costs, performance, and partner accountability. A complete visibility solution brings these areas together in a single, unified view.

Order & Shipment Visibility

Visibility over the end-to-end movement of goods, from order placement through final delivery. It includes status updates, transit milestones, estimated arrival times, and exception tracking. Order and shipment visibility helps logistics teams stay ahead of delays, verify fulfillment against expectations, and keep end customers informed.

Inventory & Production Visibility

Inventory and production visibility provide insight into where goods are, how much is available, and what’s still in the pipeline. This includes stock across warehouses, in transit, and on order, as well as updates on manufacturing or assembly progress. These insights help teams avoid stockouts and maintain production schedules to meet demand.

Supplier & Carrier Visibility

This focuses on partner performance and communication. It tracks shipment execution, responsiveness, adherence to service-level expectations, and completeness of documentation. By making supplier and carrier activity visible, teams can address issues faster and improve accountability across the network.

Financial Visibility

Financial visibility connects physical supply chain activity with associated costs. It allows organizations to see charges in context, track against contracted rates, and validate invoices as shipments move through the system. With this level of visibility, freight spend becomes more transparent and easier to manage proactively.

Challenges in Achieving Supply Chain Visibility

Even as supply chain visibility becomes a priority, many companies face obstacles that prevent them from achieving a complete, real-time view of their operations. In fact, 49% of manufacturers report that supply chain, logistics, and transportation challenges are the top trend impacting their business, highlighting the critical role visibility plays in managing disruption and staying competitive.

- Data inaccuracy and fragmentation: Poor data quality and inconsistent formats can create blind spots, especially when information is pulled from multiple systems or external partners. Without a reliable foundation, visibility loses value.

- Lack of integration across systems: Disconnected ERPs, TMSs, WMSs, and partner platforms make it difficult to track shipments, costs, and documents in one place. This slows down decision-making and increases reliance on manual work.

- High implementation costs: Building custom integrations or replacing legacy systems can be expensive and time-consuming. Many organizations delay visibility initiatives due to concerns about budget, resources, or ROI.

- Resistance to change: Visibility efforts often stall due to reluctance from both users and decision-makers. Operational teams may be hesitant to shift away from familiar tools, while leadership may be slow to approve investments without clear short-term returns.

Organizations that overcome these challenges often start by focusing on integration rather than replacement. Cloud-based platforms can layer on top of existing systems to unify data without disrupting operations. Others prioritize automating routine tasks like invoice matching and exception reporting to reduce manual effort and improve accuracy. The most successful visibility initiatives are phased in strategically, starting with high-impact use cases that deliver quick wins and build momentum for broader adoption.

Steps to Improving Supply Chain Visibility

Supply chain visibility demands the right infrastructure to connect, standardize, and interpret data across the entire network. Visibility is built step by step, starting with the source and ending with the tools that help teams make smarter decisions.

Step 1: Leverage Real-Time Data

Visibility starts with timely, accurate data. This includes inputs from IoT sensors, EDI and API connections, and shipment status updates from carriers, suppliers, and internal systems. Every scan, delay, or document creates a data point that contributes to a broader operational picture. Without consistent real-time data, downstream processes lack the context needed for confident decision-making.

Step 2: Integrate Systems and Platforms

Collected data must be synchronized across systems such as ERPs, WMSs, and TMSs to create a unified view of operations. This step involves correlating formats, timestamps, and identifiers so every transaction can be tracked from origin to delivery. Comprehensive integration reduces manual effort, eliminates discrepancies, and ensures all stakeholders are working from the same information.

Step 3: Use Advanced Analytics for Insights

Once data is centralized, analytics tools can be applied to monitor performance, identify trends, and generate actionable insights. AI and predictive modeling help anticipate disruptions, detect anomalies, and prioritize issues before they escalate. These insights move teams from reactive management to proactive planning.

Step 4: Implement Dashboards and Alerts

Dashboards and alerts make visibility actionable by surfacing real-time information across departments. Whether tracking delays, cost discrepancies, or exception events, these tools help users stay ahead of issues and respond with clarity. With the right supply chain visibility software, teams gain not only transparency but the ability to take control.

The Benefits of Supply Chain Visibility

Visibility is about building a connected supply chain that runs on reliable, real-time information. When data is accessible, consistent, and aligned across the network, teams can reduce costs and make better decisions to drive the business forward. The operational impact reaches far beyond the transportation function.

Reduce Freight Spend

When freight costs are spread across numerous modes, carriers, and regions, it’s easy to lose sight of what’s actually being spent. Supply chain visibility consolidates financial information so teams can track against contracted rates, verify charges, and catch unexpected fees before they impact the bottom line. Instead of relying on periodic audits, teams gain ongoing insight into where money is going and how costs can be better managed.

Facilitate Partner Collaboration

Visibility gives every stakeholder the same information at the same time. Shipment status, documentation, and exceptions no longer sit in separate systems or email threads, reducing the risk of miscommunication and delays. This context strengthens coordination with suppliers, carriers, and customers by enabling faster answers and more informed conversations.

Respond to Risks & Exceptions Faster

Delays, route changes, and service failures happen every day, but most teams don’t surface these issues until it’s too late to act. With real-time visibility, teams can identify potential exceptions early and take corrective steps before those issues escalate. That reduces downstream impact and helps prevent missed deliveries, added costs, or inventory gaps that disrupt operations.

Centralize Logistics Data

Many teams manage logistics through a collection of tools that are not fully connected. Supply chain visibility solutions replace this fragmented approach with a unified view of operational and financial information. When shipment events, documents, rates, and performance data live in the same environment, teams spend less time searching for answers and more time acting on them.

Data-Driven Planning

Effective planning relies on the ability to understand patterns, anticipate variability, and evaluate potential outcomes. Visibility provides the historical and real-time data needed to analyze performance, assess cost trends, and model future scenarios. These insights support better forecasting and a more confident long-term strategy.

5 Supply Chain Visibility Trends in 2026

Expectations around visibility continue to evolve as global supply chains face greater pressure to perform. The next wave of innovation will focus on turning real-time data into smarter decisions and more resilient operations.

Increased Use of AI and Predictive Analytics

AI is helping companies shift from descriptive reporting to predictive decision-making. With cleaner data inputs and stronger modeling tools, teams can anticipate delays, detect anomalies, and adapt plans in real time. It’s already becoming a standard capability: according to PwC’s Digital Trends in Operations Survey, 53% of supply chain leaders say they’re actively using AI to anticipate and mitigate disruptions. As adoption continues, AI will increasingly automate low-value tasks and surface relevant information, allowing teams to focus on strategic decisions.

Automation to Improve Efficiency

Supply chains still depend on manual processes that slow down operations and increase the risk of errors. Automation powered by visibility platforms can streamline everything from shipment tracking to invoice validation. The result is faster execution and more consistent performance with less effort.

Sustainability in Supply Chain Operations

As sustainability pressures mount, visibility is becoming essential for tracking emissions, eliminating waste, and meeting regulatory expectations. Nearly 70% of supply chain executives now say that using technology to make their supply chains more agile and sustainable is their top priority for the year ahead. Accurate shipment data makes it possible to analyze mode selection, reduce empty miles, and support reporting requirements tied to ESG goals.

Hyperconnectivity and IoT

The number of connected devices continues to grow, generating a steady stream of real-time data. IoT sensors allow for more precise location tracking, condition monitoring, and asset utilization. As more companies adopt these tools, visibility will become more granular and event-driven, offering a closer view of supply chain activity as it unfolds.

Digital Twins & Simulation

Digital twin technology is gaining traction as a way to simulate supply chain networks, test new strategies, and evaluate risk scenarios before making changes in the real world. Visibility platforms will increasingly integrate with simulation tools to help teams assess the impact of different inventory models, carrier strategies, or disruption responses before any decisions are put into motion. The global digital twin market for supply chains is projected to grow at a 36.8% CAGR, reaching $224.3 billion by 2033, underscoring the increasing importance of real-time modeling in supply chain strategy.

Choosing the Right Supply Chain Visibility Solution

Many platforms offer basic tracking, but few deliver the depth and flexibility needed to support complex global operations. A comprehensive supply chain visibility solution should unify data across systems and partners, provide real-time insight into both physical and financial activity, and support action at every stage of the shipment lifecycle. Agistix Visibility is built to do exactly that – connecting order, shipment, and invoice data in one environment so teams can make faster, more informed decisions.

Frequently Asked Questions